Editorial: Anatoly Berezkin from the recently found Stoneflower3d clay printer company is delighted to present his ceramics 3d printing kit. The kit will be available at kickstarter soon. It consists of a piston driven Cartridge connected to the Auger operated Extruder by tube. It can handle a slightly diluted clay and a wide variety of other viscous materials. It will be for sale starting at €450,- !

By: Anatoly Berezkin, Stoneflower3d.com

Very soon, the owners of desktop FDM 3D printers will get a chance to print ceramics, porcelain, plaster, experiment with pulp, wax, or even food, make custom jewelry from metal clay, automatically deposit paints on canvas or soldering paste on PCBs after a single upgrade. All of this is possible with Ceramic 3D Printing KIT, developed by the Munich Startup “StoneFlower”.

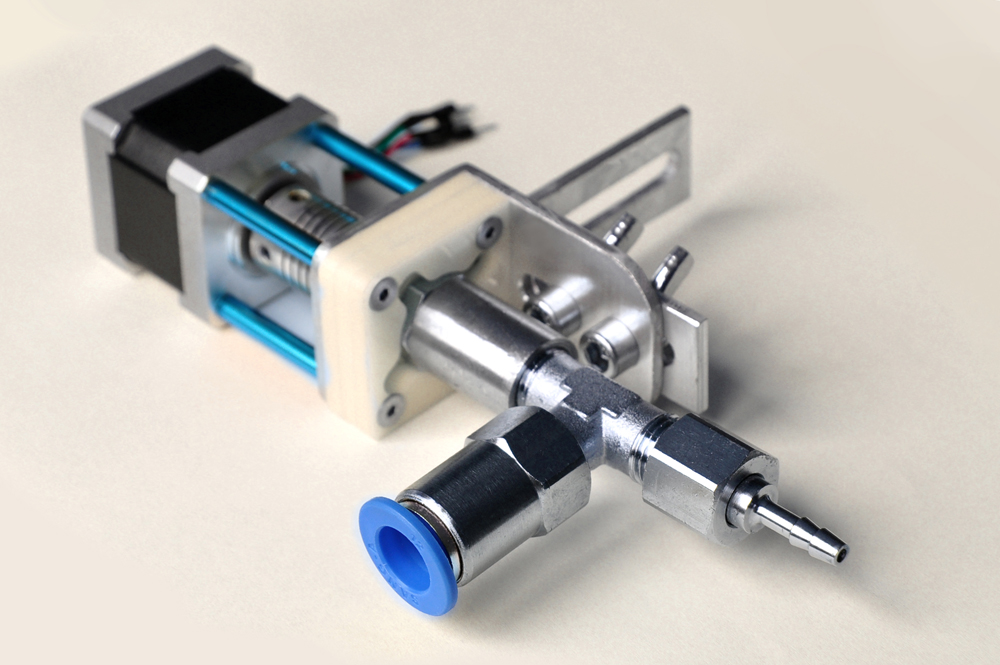

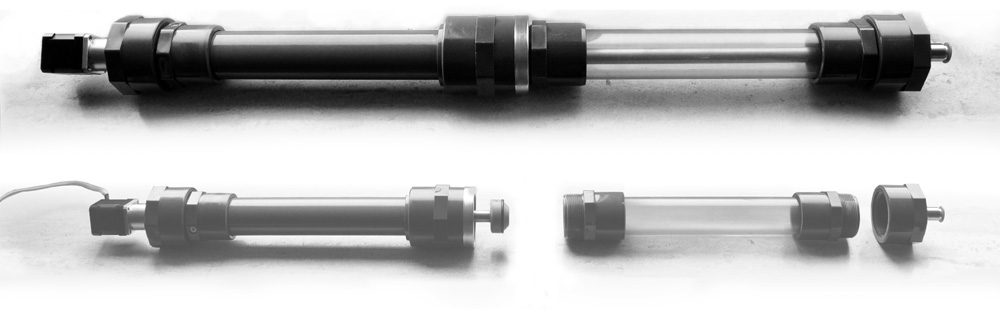

Ceramic 3D Printing KIT includes a universal print head and a syringe pump for viscous liquids and pastes that is compatible with the most of FDM printers. The print head deposits materials in layers as thin as 0.3 mm that is comparable to the accuracy of FDM 3d printing. The capacity of the pump is about 500ml or 900g of clay. The KIT will be available at Kickstarter in December 2017 for 450 euro. Delivery is planned in March 2018.

Technical details

Engineers from StoneFlower team considered a number of existing technical solutions for clay printing, and spent over 6 month to optimize mechanics, hydrodynamics and electronics of their product. They found, that the feeding of the clay and other liquids with a compressed air, being the most popular solution, has low reproducibility and requires a lot of fine-tuning. To facilitate printing, they implemented a syringe pump, which turned out to be exceptionally accurate, safe and more silent than the air compressor.

Now the StoneFlower Ceramic 3D Printing KIT works even with thick just slightly diluted clay, providing mechanically stable prints. Optimized print head, equipped with an Auger extruder, removes air bubbles from manually mixed clay and does not suffer from leaks. Moreover, this is the first print head of this kind that one can conveniently assemble and disassemble for cleaning by hands, without instruments.

Open Source

The startup StoneFlower actively contributes to the Open Source movement. The DIY-ers can benefit from the fact that the KIT has a minimum of customized parts, to simplify maintenance, component replacement and upgrades. The prototype of the clay extruder is freely available at the project web site (https://stoneflower3d.com). In the future, the startup is planning to keep posting free designs in parallel with the product development. The founders participate in specialized communities with their engineering experience.

Startup and Founders

Project StoneFlower is founded in early 2017 by Anatoly Berezkin and Stanislav Mironov. The project is aimed at the development of professional 3d printing equipment for highly viscous pseudoplastic liquids: clays, glazes, pastes, paints, curable resins etc.

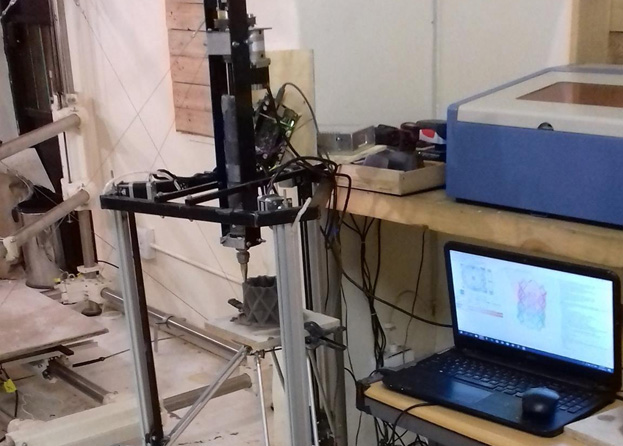

Dr. Anatoly Berezkin, being a researcher at the Max-Planck Institute in Düsseldorf, got acquainted with 3d printing of resins from liquid mixtures in the year 2013. During his collaboration with the German company Covestro AG he published a couple of research papers about the principles of this process. In the next few years at Technical University of Munich (TUM), he gained a hands-on experience in the development of automated equipment for synchrotron experiments, building CNC routers and 3d printers as a hobby. In StoneFlower Anatoly is responsible for the product development, general business management and certification.

Dipl. Eng. Stanislav Mironov has graduated from Technical University of Munich, and joined the project after internship at Electro Optical Systems GmbH (one of the world leading companies in additive manufacturing). In the startup Stanislav takes care about PR, marketing, and supply chain.

Stoneflower 3d Web site

Stoneflower 3d google community

YouTube channel

source, pictures and text: Anatoly Berezkin, Stoneflower3d.com