Author: Marlieke Wijnakker

PROFESSIONAL EXTRUDER FOR CERAMIC MATERIALS

To promote digital handcraft and self-production, WASP has focused on the development of systems that allow the use of functional materials like ceramics, porcelain, clay, alumine, zirconium and advanced ceramics.

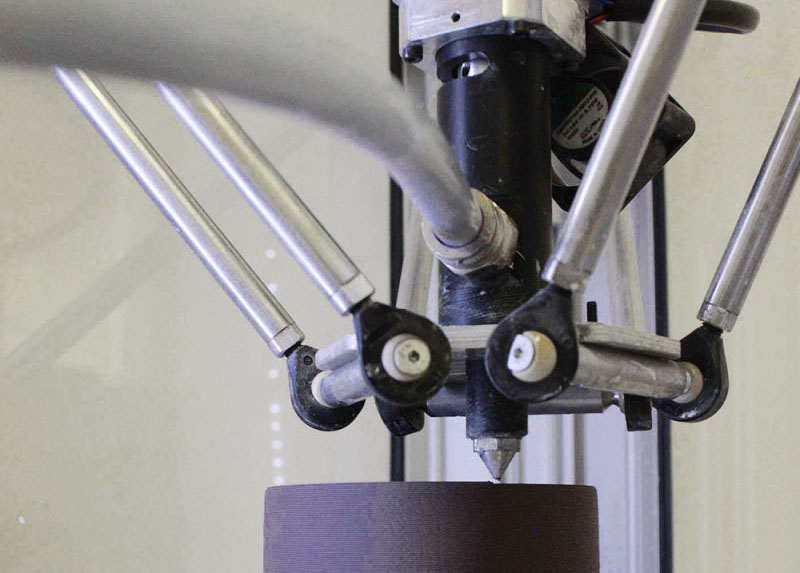

As a result of two years of experimenting all the possible combinations of pressure, nozzles and materials WASP has created another extruder which is able to interrupt and restart the extrusion flow.

Thanks to the combination of a screw extruder and a pressure extruder the new LDM Wasp Extruder can reach a level of precision which is very close to that of plastic polymers extruders. With this technology it is possible to control the flow of material using retraction to interrupt deposition.

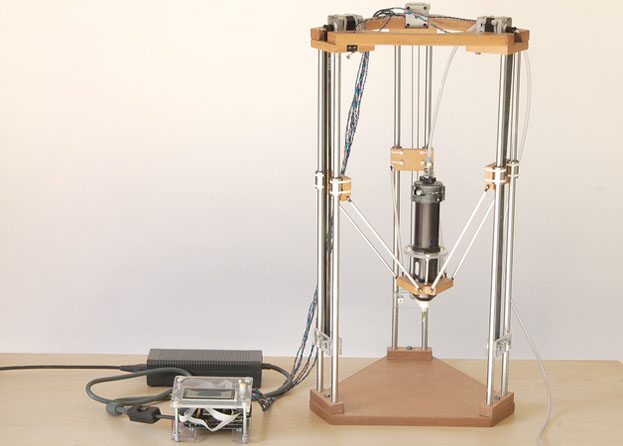

The preceding needle experimental models were unable to print middle size objects because of the limited amount of mixture they could contain. The new WASP clay kit 2.0 includes a 3 kg. tank, which can be upgraded to a 15 kg. one. The tank can be refilled or cleaned by opening the caps located at the extremes. There is a piston inside with two 4 bar gaskets to push the material through the 12mm. diameter teflon pipe which supplies the extruder. A safety valve set at 8 bar pressure is located on the back.

Both a pressure regulator and a return preventing valve are on the stand of the tank. Inside the chamber, the material is funneled toward a screw which pushes it out producing a pressure of 40 bar without damaging the system. It would be impossible to reach such a pressure level with a common pressure extruder. This technology allows the air to outflow upward, preventing most bubbles from interrupting the flow and damaging the print. Thanks to the screw, the density of the printing materials is higher. This reduces the drying time, from liquid to solid, thus eliminating the risk of collapse of the printed object. If the screw or the chamber is damaged they can be replaced easily.

The set was created for WASP printers, but can be adapted to most of the existing machines. In this case it is necessary to print the supporting cover for which the source files are provided by WASP. Then the extruder must be linked to the wire and the number of steps per millimeter must be set to 400.

These configurations are provided by the most common slicing softwares like Slic3r or Cura.

Source and pictures: waspwebsite