Editorial: Seremik is the St. Gallen-based Rapid Pottery plant that was founded by Olaf Egner

By: Admin, Semerik Swiss,

Images provided by Seremik Swiss and public record.

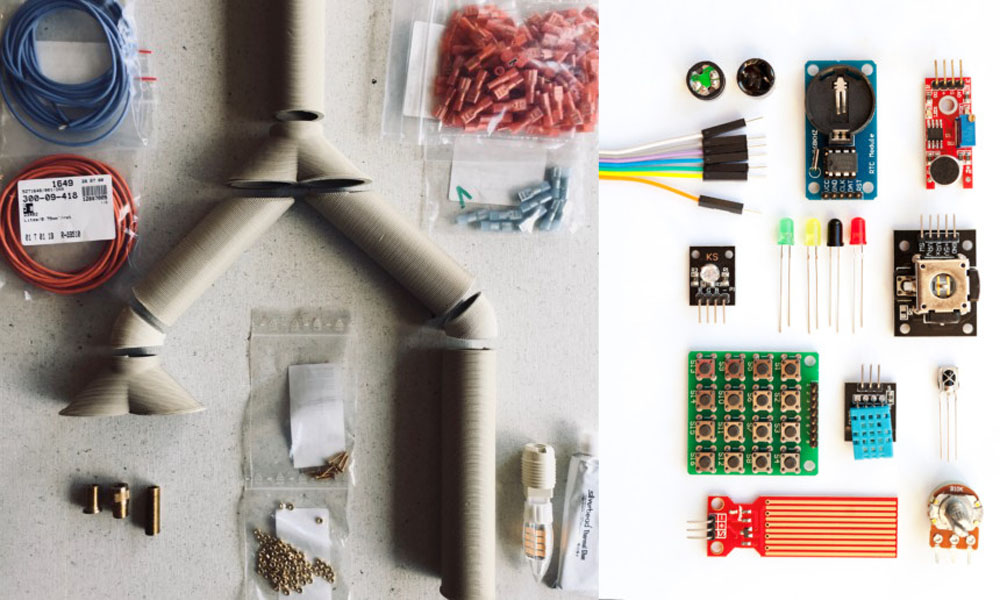

Olaf experiments in his Swiss studio with ceramic housings and vessels for electronics, lighting and audio. One of Seremik’s central goals is the development of open ensembles, in which the integration, simple exchange, re-use and repair of electronic components can be ensured.

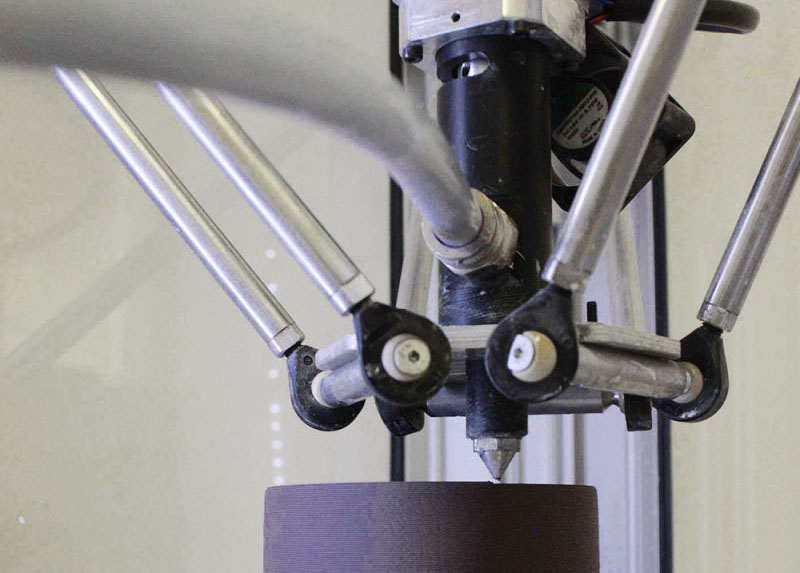

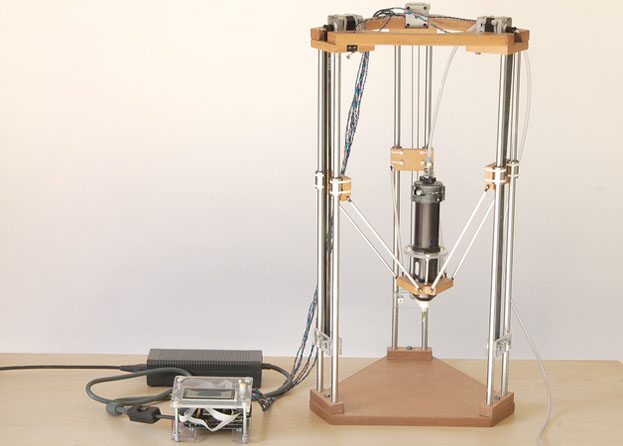

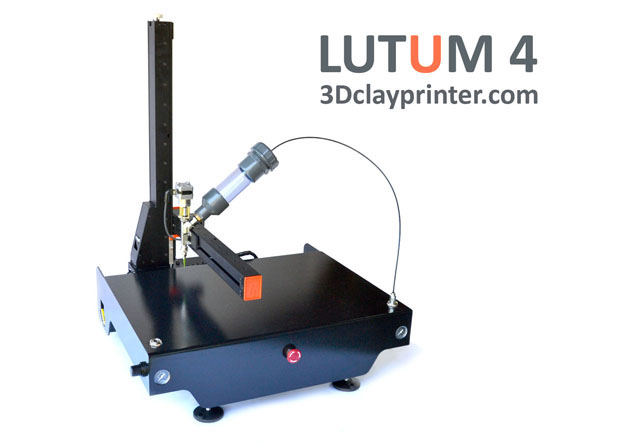

Seremik designs are created from hand-drawn sketches and rapid prototyping using Lutum 3D printers. Through the combining of printed raw clay prototypes with textiles, metals, biodegradable plastics, microcontrollers and plants, Seremik aims to find effective mixtures and relationships of dimensions, shapes and colours.

For example, during the creative process that goes into designing a lamp, the end result could be a pendant luminaire, a coffee cup, a track-mounted spotlight or a Smart Growing Farm.

FLT-DRM is a table lamp made from printed and low-fired stoneware, a wire form of an Austrian lampshade manufacturer and cotton cord from a Swiss ropemaker, textile cable from Italy, as well as installation material and lamps from China. The on-demand production in St. Gallen enables a multitude of colours, surfaces and technical variants, from a simple switch version right through to dimming- and routine control via smartphone.

FLT-DRM Lamp

Seremik and Olaf Egner are on the lookout for efficient collaborations with like-minded small manufacturers, such as glass manufacturers, metalworking companies, joineries, saddleries, and ropemakers.

These days such small scale collaborations produce amazing low volume productions. Utilizing the relative contemporary use of direct digital manufacture for ceramics makes communication and collaborative design much easier in the field of pottery while keeping the label ‘hand made’ connected to these objects.

Olaf looks forward to hearing from you!

source and images: Olaf Eger, Seremik Website