Author: Marlieke Wijnakker

Four new 3D printers started operation this month at the facility of Dutch startup Admatec, a 3D printing company that develops a wide range of printing solutions for ceramics which include material and machine.

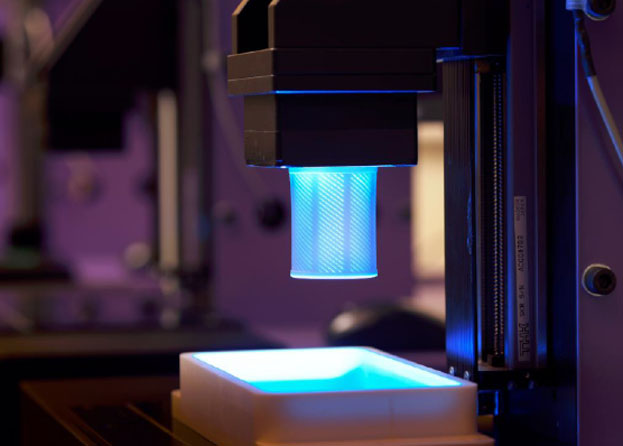

The company was founded at the end of 2012 by Formatec, ECN and Innotech and developed its ADMAFLEX technology based on the Digital Light Processing from Formatec Ceramics. Photopolymer filled with ceramic powder is exposed to light from a digital light processing projector. The light hardens the mix materials thus creating a layer of the object. The Z-platform moves up and repeats the lighting process for each new layer.

Debinding and sintering needs to be applied when the part is finished. The 3D printed product is a combination of plastics and ceramics, quite like an injection moulded product. The DLP 3D technology can produce high-resolution products with increased surface quality and product tolerances compared to powder lasering.

The ADMAFLEX technology focuses on diminishing limitations on precision, building size and speed of 3D printers designed for serial production of functional ceramic components. The technology prints with 5 to 10 mm. p/hour and features a resolution of 40 µm. and a layer thickness of 25 to 100 µm.

Printing ceramics with Admaflex 2.0.

ADMAFLEX 2.0 is used by the new 3D printers. Improvements include machine stability, processing accuracy and a software update as well as new features to increase the overall accuracy. With the ADMAFLEX 2.0 the printed ceramic parts will have a precision of +/- 0.3% of the final dimensions. Under specific circumstances this can even go to a greater precision, according to the company. Surface finishes have a Ra value of 1 micrometer.

ADMATEC believes to have the greatest capacity for printing functional ceramic components in the world. They want to prove that printing ceramics is a true manufacturing process that will significantly change the way we think about shaping ceramics today.

Material recipe, in-house developed and in-house fabricated.

The possibility of printing ceramics is being picking up by the market. For instance building complex parts for the endoscopy market. Traditionally these parts are made with ceramic injection moulding technique, but can now be printed in a very short time. And since all the elements of the value chain are internally developed and controlled, it is more economic to 3D print large amounts of these highly complex parts compared to the traditional methods.

“Significantly changing the way we think about shaping ceramics”

In the coming period ADMATEC will enter the markets of microreactors and dental application. The benefits of printing ceramics for microreactors directly involve the possibilities of printing complex structures and eliminate assembly steps. And the degree of design freedom, printing speed and elimination of material waste is a great advantage for printing dental solutions.

Source and pictures: Admatec website