Lay-Ceramic – overview

If you own a printer and like to experiment, get ready to freak out! You can now squeeze ceramic objects through the nozzle of your 3D printer.

The creation of Lay-Ceramic is inspired by enthusiasts like Dries Verbruggen (Unfold) who is working with his porcelain paste extruders since some years.

Lay-Ceramic – 3.0 mm filament / printable at about 250° – 280°C

Unlike the PORO-LAY which is full of pores after flushing with water, the Lay-Ceramic is a filled filament. “I tried to fill ceramic powder (started more than two years ago) into my polymer blends to see what would happen in a procedure of 1. printing with my home reprap; 2. debindering the polymer component in a temperature controlled oven / kiln; 3. sintering the remaining mineral object to a hard ceramic by heating up to 1200°C; 4. glazing the object with enamels to make it waterproof or decorative,” says Kai.

With the Lay-Ceramic filament you can create objects that can be fired to hard pottery.

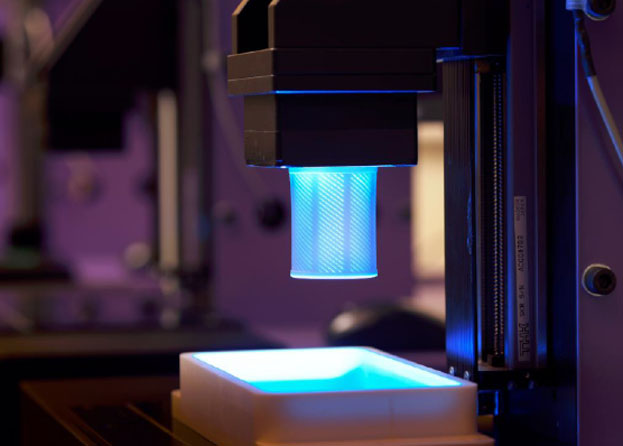

Lay-Ceramic – printing with heated bed and full metal hotend on a PRUSA i3

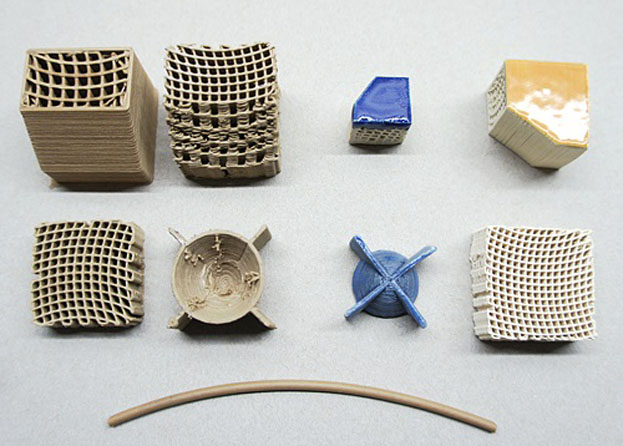

3D printed small sized objects. Left: size 2 x 2 cm, printed with 3 mm filament

Lay-Ceramic 3D printed object during a debindering process (pyrolysis), the polymeric binder is

already cracked.

To work with Lay-Ceramic, your printer needs some modifications. Kai explains:

“A full metal hotend from PRUSA or E3D is required. Quick and effective warming and good cooling fans are necessary for my “filled” filament.

“You will also need a hobbed bolt made from hardened steel which you can get from ebay. A hobbed bolt must provide a good grip on the filament because the molten filament is very viscous and is resistant against being pushed into the hotend.

“Aside from above parts, you will need a filament heater, a flexible tube to heat the filament up to 35-40 degrees. And this will make the filament less brittle.”

Heat-treatment

After the object is printed, this “green” ceramics undergoes a heat-treatment to produce a rigid, finished product. You will need a kiln, a ceramic firing oven which you can find on ebay and a temperature controller (under 80 Euro) in stepwise debindering process in a range from 250° to 500°C and a sintering process up to max. 1200°C.

3D printed objects fired at about 1200°C

fired objects / glazed in a second step

fired thinwall object / 0.6 mm nozzle / one perimeter

Future improvements

The Lay-Ceramic is still in an experimental process. “I have only tested with small objects because my oven has only a small opening.” Kai says he is working on improvements for the current version. First of all, the debindering process has to be optimized for thick wall objects. Then he wants to reduce shrinkage during firing. “In the last test I have reached a total shrinkage rate of 20-25 percent after the sintering process. I want to reduce this figure even more.” says Kai.

“Also, instead of clay or porcelain I plan to fill the basic polymer with metal-powder for printing and sintering steel objects”, added Kai.

But, like his development of POROLAY, Kai has experienced long delays and missing production capacities for some of his special filaments.

Kai has been cooperating with RepRapUniverse, the Father Franz and son Richard Achatz from Achatz-Industries in the Netherlands since late 2013 to test and print ceramic with standard Prusa i3 printer with modified hardware.

“Up to today, we have tested several compositions of ceramic filaments distributed by Kai and we are currently running a modified Prusa i3 prototype 3D printer printing LAY-Ceramic with success. There are still some minor technical issues that need to be tackled but we are very confident to have a ready-to-sell solution within the next couple of months.” says Achatz.

“We believe that potters and ceramic enthusiasts who wanna start in 3D printing will be happy to get a printer that can print standard thermoplastics as PLA, ABS or Nylon, but also is tuned for ceramic.” says Kai.

Below are some pictures of the current status of the prototype Prusa i3 Achatz Edition 3D Printer printing the LAY-Ceramic filament.