By: Yao van den Heerik

Project Sponsored by PHASE XI Germany

PHASE XI is a project from the Competence Center for the Cultural and Creative Industries of the Federal Government of Germany within the framework of the Cultural and Creative Industries Initiative and is funded by the Ministry of Economic Affairs and Energy.

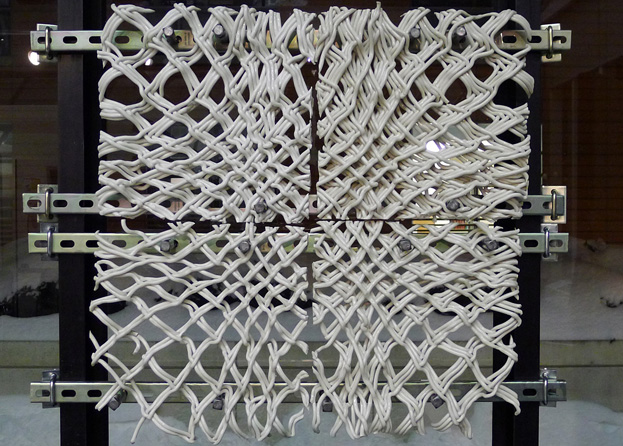

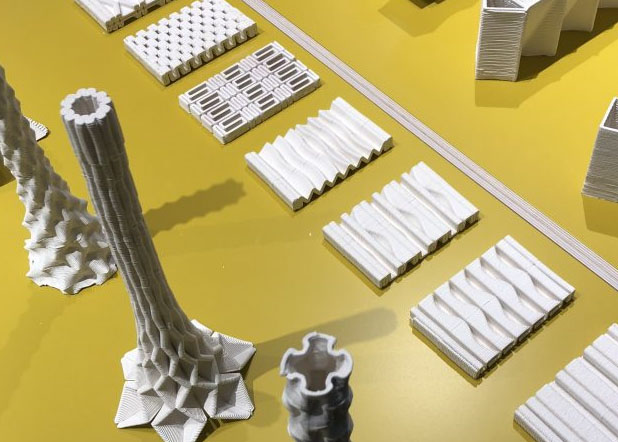

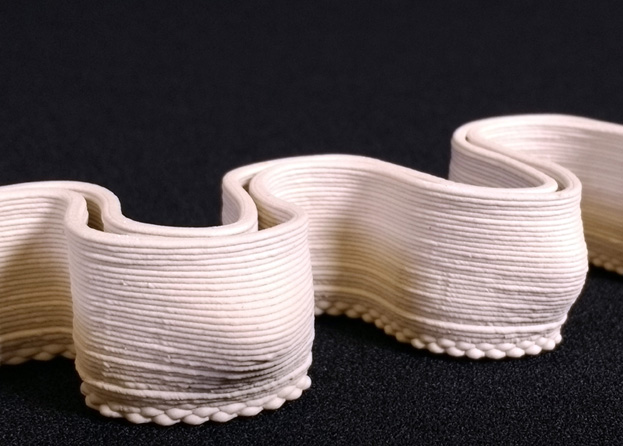

The curiosity was great: several dozen employees of the Royal Porcelain Manufactory Berlin (KPM) in Berlin crowded in the company’s own laboratory to see Alex Jentsch at work. They pelted the 31-year-old designer from the Berlin artist collective “The Constitute” with questions about his work and especially the 3D printer he had brought with him.

The meeting was one of the highlights of that fall, the one-month scholarship Jentsch used at KPM. As part of the PHASE XI project, which set itself the goal of promoting innovation in boundary crossing projects with the cultural and creative industries, it was also a kind of Clash of Cultures: on the one hand, the employees of a 260-year-old traditional company manufacturing meticulously modelled, sculpt and casted porcelain plates, cups and accessories. And on the other hand, a member of a collective of artists who try out new ideas, experiment with innovative methods and in this way want to “combine science, art and economy”. Tradition meets disruption, arts and crafts on 3-D printing, entrepreneurial hierarchy and experimental work: Could that be good?

A delicate issue to think about

KPM had not been involved with the scholarship grant, which was initiated by the Competence Center for Cultural and Creative Industries of the Federal Government. “We certainly saw the danger that our employees get the impression that they should soon be replaced by machines,” says CEO Bernd Lietke.

On the other hand, it is important to go new ways and to deal intensively with new technologies. “That’s why we’ve always focused on transparency right from the start,” says Lietke. This included informing the works council comprehensively and organizing the busy meeting in the laboratory. Looking back, Lietke is glad that he has taken the step. “We’ve learned a lot about 3D printing in the last few weeks,” he says. “That helped to reduce fears and recognize the opportunities that technology holds for a traditional business.”

But Alex too, has benefited: “Although I have worked a lot with porcelain before, it has always been a mystery to me how to get the right consistency. The scholarship has helped me a lot further. “So both sides have clear ideas on how to better integrate the other technology into their work. And they agree that they want to continue to benefit from each other. We will continue the cooperation, this “Clash of Cultures” – it leads to a cooperation.”

Original Source: www.business-punk.com pictures by:The Constitute

Original Author: Daniel Schönwitz