Author: Marlieke Wijnakker

A different approach to 3D Printing

Dutch designer, Daniël de Bruin worked with 3D printers for quite some time, but there was one thing bothering him. The results of the printer didn’t feel like personal achievements anymore. They were products of this new technology. A machine did all the work. He therefor decided to make his own printer in order to regain the feeling of creating.

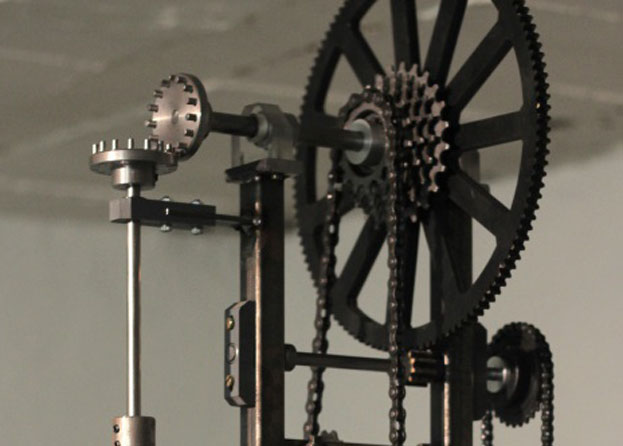

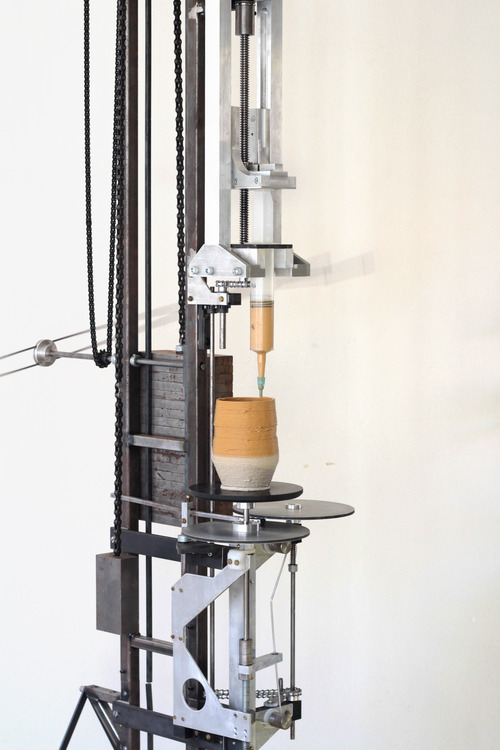

De Bruin wanted to stay as close to the new technology as possible but without any external forces like electricity or programming. As a Product design student at the University of Arts in Utrecht, his background of model making and architecture helped him achieve his first creation. An analog 3D Clay Printer which doesn’t need any electrical source or computer software.

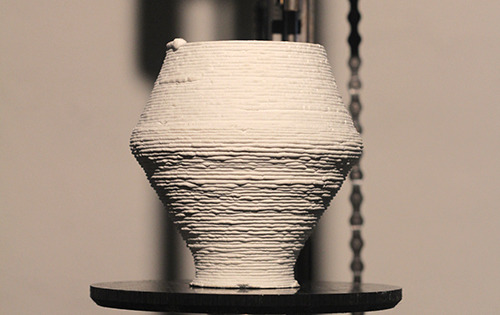

He started with the main components like the pressing and driver mechanism. Once this part was made, the printing platform followed, resulting in a vertical oriented shape.

This 3D printer is turned on when 15 kg. of weight is manually lifted by the user. The weight takes about 10 minutes to return to the end position. So to keep the process going the user must lift it every 10 minutes. This allows the user to remain involved in the process rather than just looking at it do everything for you. As there is no external force like electricity it still feels like the user is making the print. Therefor the products that come out are the direct result of all the energy that has gone into it by physically building and powering the machine.

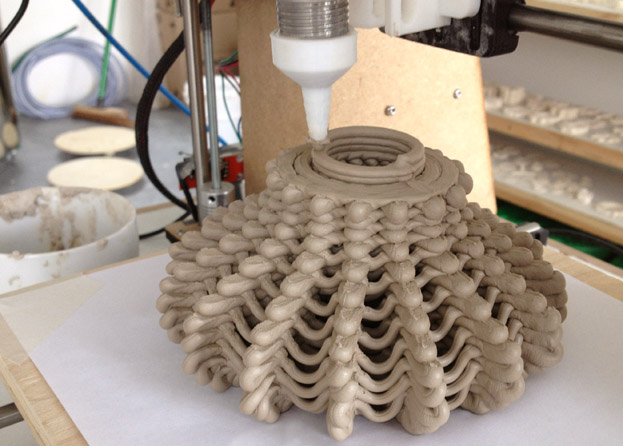

An aluminium wire attached to the printing platform controls the shape of the print. When the platform rotates downwards, the different shapes of the wire change the motion of the platform and cause changes in the radius of the circle.

To print different sized round objects this wire can easily be formed into any desired shape. And all this can be done with just one rotating axis.

It took De Bruin nine months of his spare time to create this 3D printer. The most challenging part was keeping the same wall thickness as the radius became larger. He decided to change the speed of the platform since the extrusion rate remains the same. De Bruin added one driven plate and one following plate on the guiding mechanism and connected them with a small wheel. The motion of the following plate changes the speed of the driven plate and causes the platform to spin slower or faster.

This 3D printer is equipped with a 2mm. nozzle and works with clay. As clay is used in a paste shape it also allows you to experiment with other pastes that don’t need heating afterwards. It cost De Bruin only €150 on materials but the device is not for sale. The outcome is still limited as it can only create round shapes.

De Bruin will be graduating next year. In the meantime he is still busy improving his printer. He may even make an updated version of this one.

This New Technology – World’s first analog 3D printer from DANIELDEBRUIN on Vimeo.

Source and pictures: Daniël de Bruin website