A dislodged X-arm You Managed to Dislodge the X-arm from the vertical mechanics in the Z-Pole…

You managed to Dislodge the X-arm from the vertical mechanics in the Z-Pole…

How to solve this quickly.

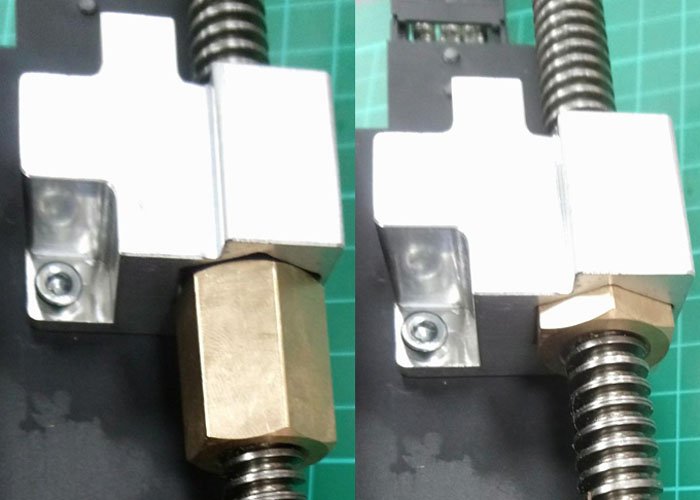

The bronze Z-spindle-nut is dislodged from its aluminium socket.

This is normal for emergencies when the X-arm is moving down lower than physically possible or because of an obstruction on the Print bed or because the long nozzle is attached but the Z slider was not moved up to set the correct zero point for Z homing.

What you need to do is to take the power off the printer.

1 person needs to hold the arm up.

The other person needs to move the Bronze nut up towards the four slides (openings) on the back of the vertical arm to visually inspect the situation.

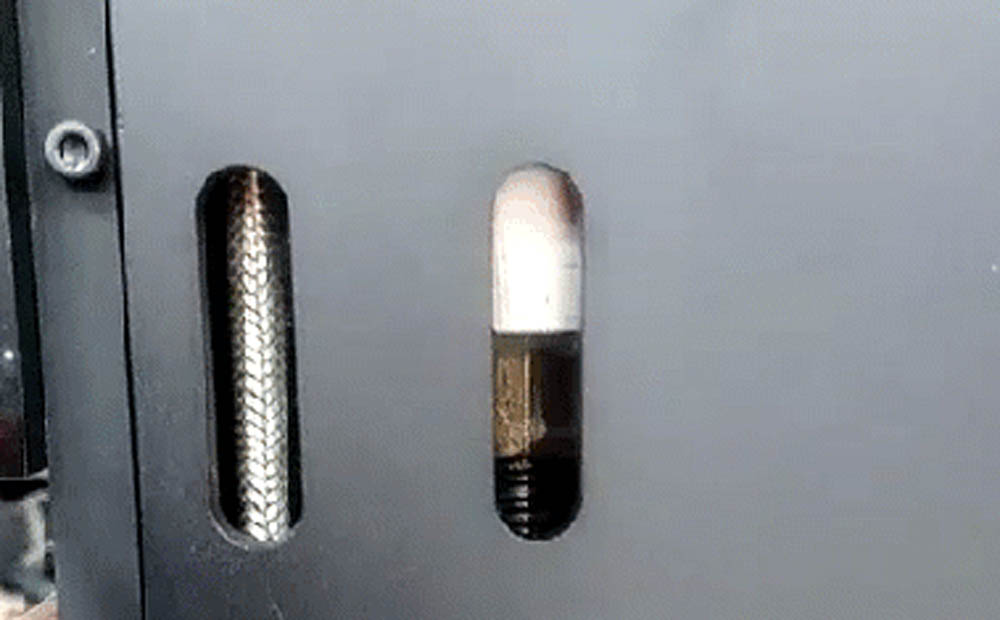

- Use the wheel on top of the Z arm to move the Bronze nut up.

- Hold the nut with a screwdriver Through the side slid running along the Z-pole while turning the wheel.

- Turn the Bronze nut in the correct position so it can slide into the socket.

- Slowly slide the X arm down and place the nut back into the socket.

- You might need a small hook or screwdriver to push/pull the Z-spindle so that the Nut aligns perfectly with the socket.

- It is a very tight fit, but it does fit.

Once it slides in make sure you do not lift the arm assembly while holding the X arm as you would dislodge the Nut again.

Done!